As modern industry continues to develop at a rapid pace and people's living standards continue to improve, the demand for folding cartons will continue to rise, as will the quality of folding cartons, which will be held to higher standards as a result of these developments. -It is necessary to ensure that the paper tray structure size design is reasonable in order for the automatic folding paste mailer box machine to avoid waste products and for the folding tray in the high-speed packaging machine to automatically complete the opening, molding, filling, and sealing processes as well as other processes. In addition, it is necessary to ensure that the paper boxes for packaging piece has sufficient die-cutting accuracy and folding boxes accuracy, among other requirements. Short-form live parts growth, improved processing quality, and cost reduction are all market pressures and difficulties that carton packaging enterprises must contend with. These pressures and difficulties necessitate the application of new technologies in the carton packaging production process, continuous improvement in the degree of automation of equipment, and reduction of equipment adjustment time as well as auxiliary preparation time for live parts. Competition can only be defined as a company's ability to continuously adapt its operations to new market conditions, as well as its ability to meet the needs of a diverse range of customers.

When you hear the term box, you're thinking of a product that is packaged in a box, as the name implies. Boxes can be divided into categories based on the materials that were used to construct them, such as: wooden box Bai, cartons, cloth boxes, leather boxes, iron boxes, ackle boxes, corrugated boxes, and other similar items. They can also be divided into categories based on the products that they are used to package, such as gift boxes, wine boxes, chocolate boxes, pen boxes, food boxes, and tea boxes, among others. A composite made of wood, paper, and other materials that are all produced together has evolved into what is known as a composite board. Products are packaged in this manner in order to ensure their safety during transportation and to improve their overall quality during storage.

Materials are classified according to a set of criteria that are applied.

Both paper and pit paper fall into the following two broad categories: paper and pit paper, both of which are listed below. Colors of box paper that are frequently used include: gray copper, white copper, single copper, gorgeous card, gold card, platinum card, silver card, laser card, and so on. Colors of box paper that are not commonly used include: white copper, gray copper, single copper, gorgeous card, platinum card, silver card, laser card, and so on. The following are examples of other colors: laser card, silver card, and so on.

Single copper and white copper are the two types of copper used in the construction of a whiteboard. There is only one thing in common between white copper and single copper, and that is the fact that they are both white on both sides. With white copper, the difference is that one side is smooth and the other side is not smooth, resulting in a textured surface on one side. The fact that only the front can be printed and that the reverse cannot is a feature that is extremely popular with customers. In the case of single copper, both the front and back surfaces are coated, allowing for printing on both the front and back surfaces.

When used on the gray-bottomed gray board, it is referred to as grey copper paper, which means that the front of the paper is white and can be printed, while the opposite side is gray and cannot be printed. When used on the box, it is referred to as gray copper paper, which means that the front is white and can be printed, while the opposite side is gray and cannot be printed. However, with the exception of a few special white cards such as platinum or silver card, the general white card is identical to the general quotation (with the exception of special white cards such as platinum or silver card, and so on). Custom Paper Boxes are made of a variety of materials.

One-sided white powdered paper with a gray backside; the price is low for this type of paper. Second, the price of double powder paper is very high; both sides are white on both sides. The price is low for powdered paper that has one side that is white and one side that is gray.

Secondly, the shape and size of the product have an impact on the color of the packaging material.(1)Powdered ash paper is commonly used in a variety of packaging box applications, including 280g of powdered ash paper, 300g of powdered ash paper, 350g of powdered ash paper, 250g of powdered ash E pit, 250g double-powdered paper E pit, and various other packaging box applications.

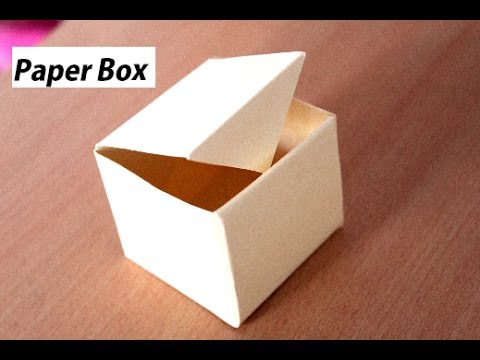

A clamshell package is a type of paper packaging that is used in between the inner package and the outer box packaging and is used in between the inner package and the outer packaging. It is a color Custom Packaging Box Supplier that is generally composed of a number of colors and provides people with a strong visual sense, allowing buyers and users to gain a better understanding of the overall appearance and color of the goods, as well as other details.

The use of this method is particularly advantageous for items that cannot be unboxed before purchase. A wide range of industries, including electronics, food and beverage, alcohol and tobacco products; medicine; health care products; cosmetics; small household appliances; clothing; toys; sporting goods; and other industries and product packaging supporting industries, make extensive use of this material. Several industries, including electronics, food and beverages, as well as alcoholic beverages, tea and cigarettes, rely on this industry for their survival.